Solid-propellant rocket

Solid-propellant rocket

Propellants

A solid-propellant rocket or solid rocket is a rocket with a rocket engine that uses solid propellants (fuel/oxidizer). The earliest rockets were solid-fuel rockets powered by gunpowder. The origin of gunpowder rockets can be attributed to ancient Chinese.

All rockets used some type of form of solid or powdered propellant up until the 20th century, after which liquid-propellant rockets offered more efficient and controllable alternatives. Solid rockets are still used today in military worldwide, model rockets, solid rocket boosters and on larger applications for their simplicity and reliability.

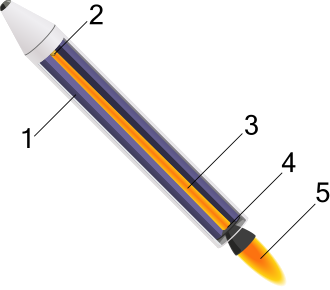

A simple solid rocket motor consists of a casing, nozzle, grain (propellant charge), and igniter.

The solid grain mass burns in a predictable fashion to produce exhaust gases, the flow of which is described by Taylor-Culick flow. The nozzle dimensions are calculated to maintain a design chamber pressure, while producing thrust from the exhaust gases.

Once ignited, a simple solid rocket motor cannot be shut off, because it contains all the ingredients necessary for combustion within the chamber in which they are burned. More advanced solid rocket motors can be throttled, and also be extinguished, and then re-ignited by control of the nozzle geometry, or through the use of vent ports. Further, pulsed rocket motors that burn in segments, and that can be ignited upon command are available.

Modern designs may also include a steerable nozzle for guidance, avionics, recovery hardware (parachutes), self-destruct mechanisms, APUs, controllable tactical motors, controllable divert and attitude control motors, and thermal management materials.

Design begins with the total impulse required, which determines the fuel and oxidizer mass. Grain geometry and chemistry are then chosen to satisfy the required motor characteristics.

The following are chosen or solved simultaneously. The results are exact dimensions for grain, nozzle, and case geometries:

- The grain burns at a predictable rate, given its surface area and chamber pressure.

- The chamber pressure is determined by the nozzle throat diameter and grain burn rate.

- Allowable chamber pressure is a function of casing design.

- The length of burn time is determined by the grain "web thickness".

- The grain may or may not be bonded to the casing. Case-bonded engines are more difficult to design, since the deformation of the case and the grain under flight must be compatible.

Common modes of failure in solid rocket motors include fracture of the grain, failure of case bonding, and air pockets in the grain. All of these produce an instantaneous increase in burn surface area and a corresponding increase in exhaust gas production rate and pressure, which may rupture the casing.

Another failure mode is casing seal failure. Seals are required in casings that have to be opened to load the grain. Once a seal fails, hot gas will erode the escape path and result in failure. This was the cause of the Space Shuttle Challenger disaster.

|

| The Space Shuttle was launched with the help of two solid-fuel boosters known as SRBs; source: Wiki |

Propellants

Black powder (gunpowder) propellant

Black powder (gunpowder) is composed of charcoal (fuel), potassium nitrate (oxidizer), and sulfur (fuel and catalyst). It is one of the oldest pyrotechnic compositions with application to rocketry. In modern times, black powder finds use in low-power model rockets (such as Estes and Quest rockets), as it is cheap and fairly easy to produce. The fuel grain is typically a mixture of pressed fine powder (into a solid, hard slug), with a burn rate that is highly dependent upon exact composition and operating conditions. The specific impulse of black powder is low, around 80 s (0.78 km/s). The grain is sensitive to fracture and, therefore, catastrophic failure. Black powder does not typically find use in engines above 40 newtons thrust.

Zinc–sulfur (ZS) propellants

Composed of powdered zinc metal and powdered sulfur (oxidizer), ZS or "micrograin" is another pressed propellant that does not find any practical application outside specialized amateur rocketry circles due to its poor performance (as most ZS burns outside the combustion chamber) and fast linear burn rates on the order of 2 m/s. ZS is most often employed as a novelty propellant as the rocket accelerates extremely quickly leaving a spectacular large orange fireball behind it.

"Candy" propellants

In general, rocket candy propellants are an oxidizer (typically potassium nitrate) and a sugar fuel (typically dextrose, sorbitol, or sucrose) that are cast into shape by gently melting the propellant constituents together and pouring or packing the amorphous colloid into a mold. Candy propellants generate a low-medium specific impulse of roughly 130 s (1.3 km/s) and, thus, are used primarily by amateur and experimental rocketeers.

Double-base (DB) propellants

DB propellants are composed of two monopropellant fuel components where one typically acts as a high-energy (yet unstable) monopropellant and the other acts as a lower-energy stabilizing (and gelling) monopropellant. In typical circumstances, nitroglycerin is dissolved in a nitrocellulose gel and solidified with additives. DB propellants are implemented in applications where minimal smoke is required yet a medium-high Isp of roughly 235 s (2.30 km/s) is required. The addition of metal fuels (such as aluminium) can increase performance to around 250 s (2.5 km/s), though metal oxide nucleation in the exhaust can turn the smoke opaque.

Composite propellants

A powdered oxidizer and powdered metal fuel are intimately mixed and immobilized with a rubbery binder (that also acts as a fuel). Composite propellants are often either ammonium-nitrate-based (ANCP) or ammonium-perchlorate-based (APCP). Ammonium nitrate composite propellant often uses magnesium and/or aluminium as fuel and delivers medium performance (Isp of about 210 s (2.1 km/s)) whereas ammonium perchlorate composite propellant often uses aluminium fuel and delivers high performance: vacuum Isp up to 296 s (2.90 km/s) with a single-piece nozzle or 304 s (2.98 km/s) with a high-area-ratio telescoping nozzle. Aluminium is used as fuel because it has a reasonable specific energy density, a high volumetric energy density, and is difficult to ignite accidentally. Composite propellants are cast, and retain their shape after the rubber binder, such as Hydroxyl-terminated polybutadiene (HTPB), cross-links (solidifies) with the aid of a curative additive. Because of its high performance, moderate ease of manufacturing, and moderate cost, APCP finds widespread use in space, military, and amateur rockets, whereas cheaper and less efficient ANCP finds use in amateur rocketry and gas generators. Ammonium dinitramide, NH4N(NO2)2, is being considered as a 1-to-1 chlorine-free substitute for ammonium perchlorate in composite propellants. Unlike ammonium nitrate, ADN can be substituted for AP without a loss in engine performance.

High-energy composite (HEC) propellants

Typical HEC propellants start with a standard composite propellant mixture (such as APCP) and add a high-energy explosive to the mix. This extra component usually is in the form of small crystals of RDX or HMX, both of which have higher energy than ammonium perchlorate. Despite a modest increase in specific impulse, implementation is limited due to the increased hazards of the high-explosive additives.

Composite modified double base propellants

Composite modified double base propellants start with a nitrocellulose/nitroglycerin double base propellant as a binder and add solids (typically ammonium perchlorate (AP) and powdered aluminium) normally used in composite propellants. The ammonium perchlorate makes up the oxygen deficit introduced by using nitrocellulose, improving the overall specific impulse. The aluminium improves specific impulse as well as combustion stability. High performing propellants such as NEPE-75 used to fuel the Trident II D-5, SLBM replace most of the AP with polyethylene glycol-bound HMX, further increasing specific impulse. The mixing of composite and double base propellant ingredients has become so common as to blur the functional definition of double base propellants.

Minimum-signature (smokeless) propellants

One of the most active areas of solid propellant research is the development of high-energy, minimum-signature propellant using C6H6N6(NO2)6 CL-20 nitroamine, which has 14% higher energy per mass and 20% higher energy density than HMX. The new propellant has been successfully developed and tested in tactical rocket motors. The propellant is non-polluting: acid-free, solid particulates-free, and lead-free. It is also smokeless and has only a faint shock diamond pattern that is visible in the otherwise transparent exhaust. Without the bright flame and dense smoke trail produced by the burning of aluminized propellants, these smokeless propellants all but eliminate the risk of giving away the positions from which the missiles are fired. The new CL-20 propellant is shock-insensitive (hazard class 1.3) as opposed to current HMX smokeless propellants which are highly detonable (hazard class 1.1). CL-20 is considered a major breakthrough in solid rocket propellant technology but has yet to see widespread use because costs remain high.

Electric solid propellants

Electric solid propellants (ESPs) are a family of high performance plastisol solid propellants that can be ignited and throttled by the application of electric current. Unlike conventional rocket motor propellants that are difficult to control and extinguish, ESPs can be ignited reliably at precise intervals and durations. It requires no moving parts and the propellant is insensitive to flames or electrical sparks.

Orbital rockets

Solid rockets are suitable for launching small payloads to orbital velocities, especially if three or more stages are used. Many of these are based on repurposed ICBMs:

- Scout

- Athena

- Mu

- Pegasus

- Taurus

- Minotaur

- Start-1

- Shavit

- Vega

- Long March 11

- OmegA

Larger liquid-fueled orbital rockets often use solid rocket boosters to gain enough initial thrust to launch the fully fueled rocket:

Solid rocket booster

- Delta II

- Titan IV

- Space Shuttle

- Space Launch System

- Ariane 5

- Atlas II

- Atlas V (optionally 1-5 boosters)

- Delta IV (optionally 2 or 4 boosters)

- H-IIA, H-IIB

- PSLV - optional solid boosters to lift heavier payloads

- GSLV Mk III

Comments

Post a Comment